Automatic Tension Controller Can Help The Winding And Unwinding Industry

Release Date:05/09/2019

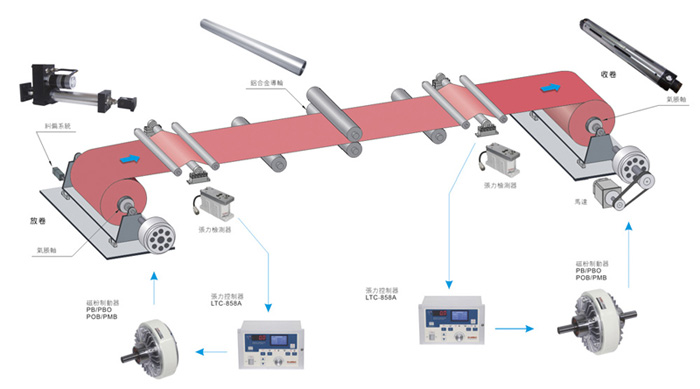

Rewinding and unwinding operations are essential in manufacturing, and these can be extremely sensitive processes that can affect the quality of the final product. For example, excessive tension applied to the tape can damage the web structure, causing it to buckle or stretch. More specifically, as the roller diameter decreases, the roller speed will increase to maintain a constant linear velocity, but the tension braking force must be adjusted to maintain the tension on the web consistent. Therefore the automatic tension controller is an essential quality assurance device.

One of the major challenges of tape manufacturing is the all-weather adjustment of web tension based on tape width and reel diameter. By applying automated solutions that constantly adapt to changing conditions, Taiji manufacturers have upgraded automatic tension controllers, improving the productivity and product quality of the reel industry.

By switching from a manual tension controller system to an automated solution, the machine operator can be released and the machine operator can then focus on other tasks. This ultimately improves the productivity and throughput of the entire system. In addition, the automatic tension controller systematically solves the problem of quality consistency encountered in the past, so the emergence of automatic tension controller is really helping the rewinding industry. The quality problems encountered before and the improvement of production efficiency.

Click the link of Taiwan machine brand automatic tension controller:

http://www.tianjidg.com/list_31.html

Prev: Slitting Machine receives the volume with special brake controller

Leave Messages

Leave Messages