Hot sale stainless Steel 24V DC Electromagnetic clutch

Product Description

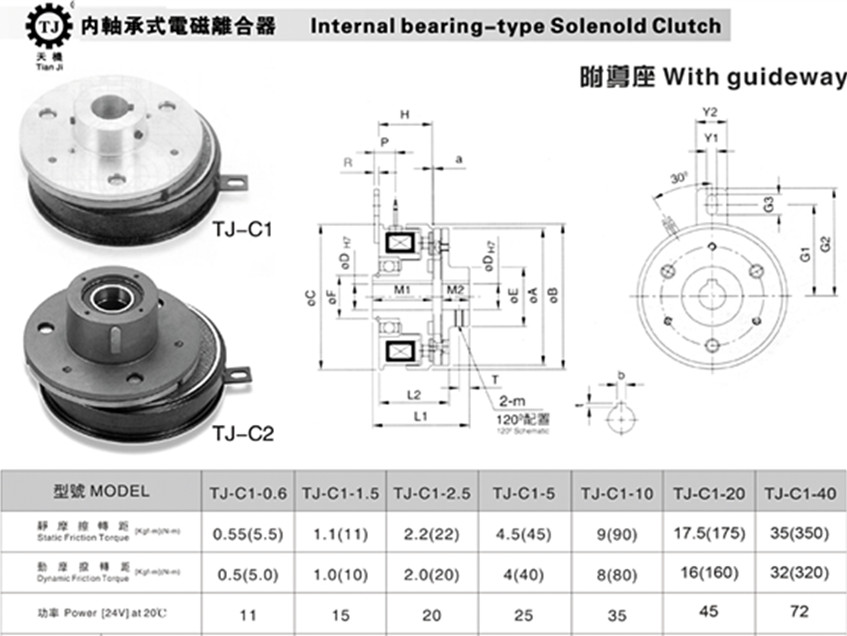

electromagnetic clutch with bearing and guideway Brief introduction

This clutch product is designed by professional engineers with many years of experiences, and production using CNC boring and finishing machines,and be proved good in all using.We use the finest materials available for magnetic components to yield high friction indexes,as well as premium non-asbestos linings to improve response time and extend working life. We will be reliable clutch supplier for you.

electromagnetic clutch with bearing and guideway Parameter

| MODEL | TJ-C1-0.6 | TJ-C1-1.5 | TJ-C1-2.5 | TJ-C1-5 | TJ-C1-10 | TJ-C1-20 | TJ-C1-40 |

| Static Friction Torque(Nm) | 5.5 | 11 | 22 | 45 | 90 | 200 | 400 |

| Dynamic Friction Torque(Nm) | 5 | 10 | 20 | 40 | 80 | 180 | 350 |

| Power (W) 24V 20°C | 11 | 15 | 20 | 25 | 35 | 45 | 60 |

| Weight (kg) | 1 | 1.5 | 2.5 | 4 | 7 | 9.8 | 17.5 |

| |||||||

electromagnetic clutch with bearing and guideway Detial TJ-C1

TJ-C2

Special features

1. Fast response. Dry design means instant reaction to commands.

2. Durability. Excellent heat dissipation and quality materials mean long life, even under high frequency and high performance conditions.

3. Easy to install and maintain. Sealed bearing race eliminates the need for removal of the center core. No dust brush is needed, and operation is simper and easier.

4. No adjustment of the motor. The motor is designed so that it does not need adjustment of the friction surface, and once it is installed only very minor adjustments are needed.

5. Sure motion. One-piece plate will not slip even under the strongest vibration for longer life.

6. Adjustable torque. Torque levels can be increased or decreased by changing the current, making it suitable for a variety of applications. |

Clik me♦

| TJ-A1 | TJ-B |

|  |

electromagnetic clutch with bearing and guideway Appliation Main application

1. Packing and wrapping system: packing machines, strapping machines, wrapping machinery.

2. Textile machinery: fiber twisters, treatment machines, weaving machines.

3. Metal finishing systems: extruders, wire stretchers, presses, welders, steel wire reactors, cutters, pipe makers, wire winding machines

4. Machine tool systems: laths, millers, steel extruders, CNC lathes, specialized machinery.

5. Transportation equipment: hoists, feeders, conveyors, rollers, winders.

6. Paper-making systems: bad-making machines, box-making machines, slitters, book-making machinery, cutters, copy paper machines. |

Our Services

Why do you choose us?

Your choice,I promise.

Eight reasons to choose us

1,Perfect service system and after-sale protection

2,Quality problems will be solved within 24hours.

3,two or more free shipping within the pearl river delta.

4,Companies carry out the ERP management, improve enterprise fast response, one-to-one customer service tracking processing.

5,Quality assurance, one year warranty.

6,Supporting professional matched other equipments.

7,The company has more than one product testing units, the implementation of ISO9001: 2008.

8,Unique development and design capabilities to meet the needs of special-purpose equipment manufacturing.

Five Core strengths

1,The first domestic independent R & D manufacturer and 13 years of professional manufacturing. Processing all adopt Taichung precision machine, CNC machine tool production,"Japan's brothers" machining center. Ensuring that the concentricity is less than 0.01 mm.

2,Casting exquisite, beautiful, practical and durable. The lids adopts aluminum die casting, the surface is smooth, precision, anti-seismic. And the hardness is strong.

3,Complete specifications, cost-effective and spot supply.

4,Independent research and development, special specifications can be customized.

5,Selected materials, high-tech treatment, up to the international standard test.

Company Information

Our factory

Our Fairs

Our market

More concerned for our products ,

More concerned for our products ,

please do not hesitate to inquiry now!

See larger image

See larger image Leave Messages

Leave Messages