Structure and working principle:

The magnetic powder clutch is composed of active rotor(input shaft), driven rotor (output shaft) and Yoke with excitation coil. The three parts are resembled against the concentric part and form a system which can rotate relatively. The annular gap between active rotor and driven rotors is full of alloy powder which has high permeability.

The magnetic powder will be in the state of loose when the current do not pass the excitation coil. The magnetic powder will be thrown on the inner wall of active rotor. In this case, there will not exist the interaction force between the active and driven rotor. Because the magnetic powder clutch is in the state of separation, no torque transmission exists.

The magnetic powder in the working chamber will link in a link state under the action of the magnetic flux generated from the Yoke when the current pass the excitation coil. The magnetic powder clutch can transfer torque relying on the shear force generated from magnetic chain and the friction generated from the magnetic powder and working face. in this case, the magnetic powder clutch is in the state of combination.

When the current is cut off, the magnetic flux will disappear with the disappearance of the magnetizing current, the magnetic powder will be in the state of loose under the action of gravity again, and will be thrown on the inner wall of active rotor under the action of the centrifugal force. In this case, the magnetic powder clutch will be in the state of separation again.

The magnetic powder clutch and brake have the same principle; the magnetic powder brake will form as long as the driven rotor of the magnetic powder clutch is fixed.

Powder clutch Advantages:

1. High linearity and high precision torque control.

2. High temperature resistant coil superalloy magnetic powder is adopted, with long service life, smooth connection and no impact magnetic powder clutch

3, CNC precision manufacturing, high precision, precision machining, good linearity, superior performance.

4, Magnetic powder high purity, no black powder, stable performance, long life.

5, Aluminum alloy structure, with excellent heat dissipation performance, good demagnetization, fast response.

Powder clutch Application:

It is widely used in printing machinery, paper industry machinery, bag-making machinery, paper-making machinery , wire and cable machinery, coil machinery, wire winding machines, strapping bag machinery, textile machinery, weaving-dimensional machinery, woodworking machinery, steel extruders, CNC lathes, specialized machinery and so on.

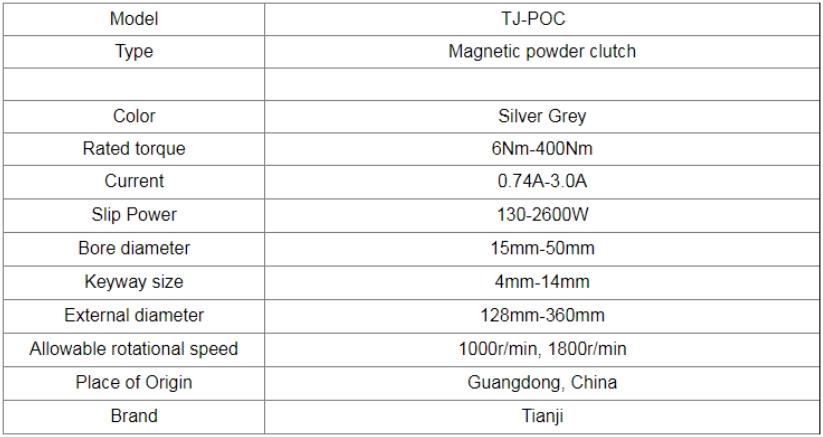

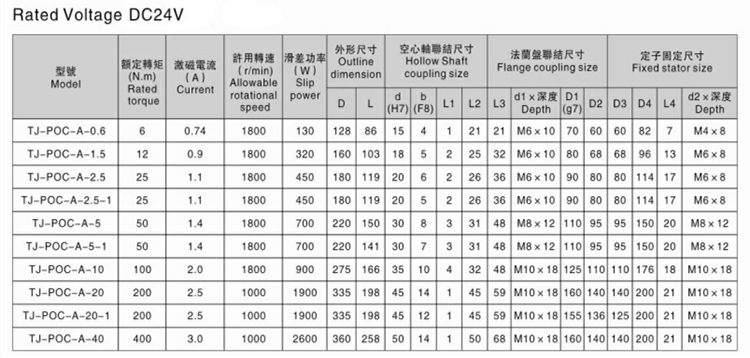

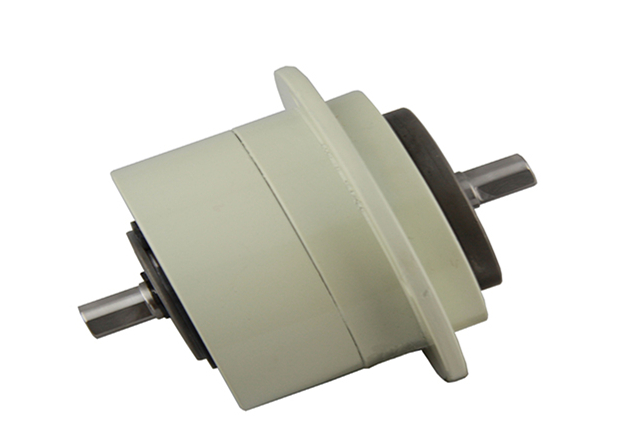

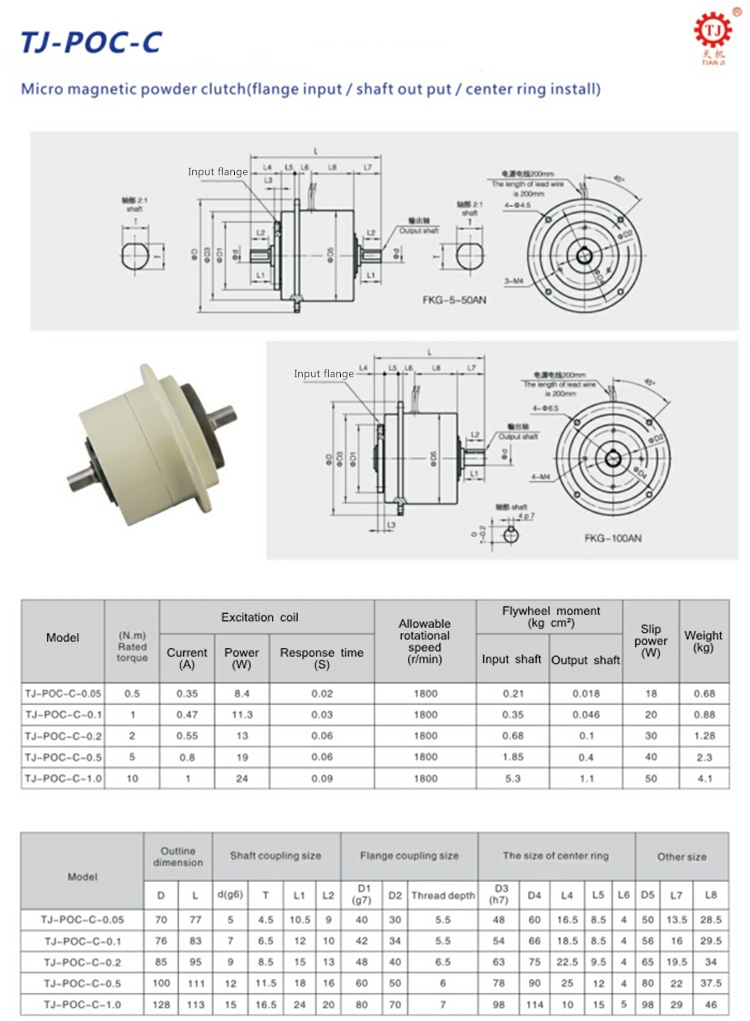

TJ-POC Powder Clutch Parameters:

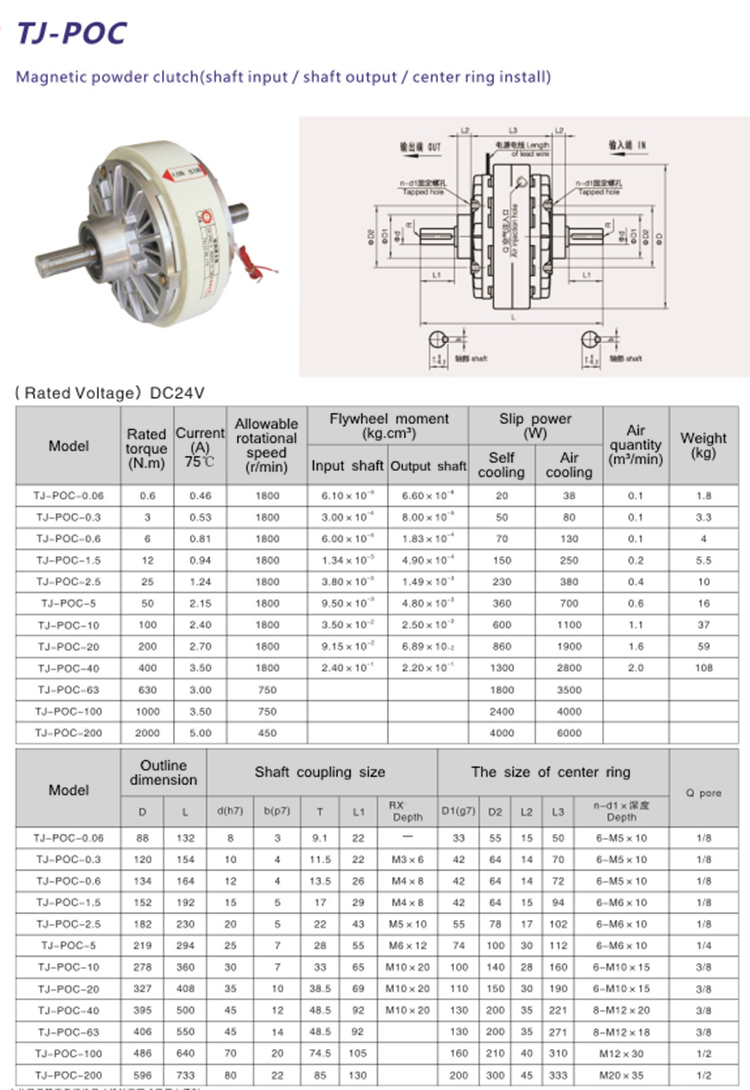

TJ-POC-A powder clutch(rotational shell)

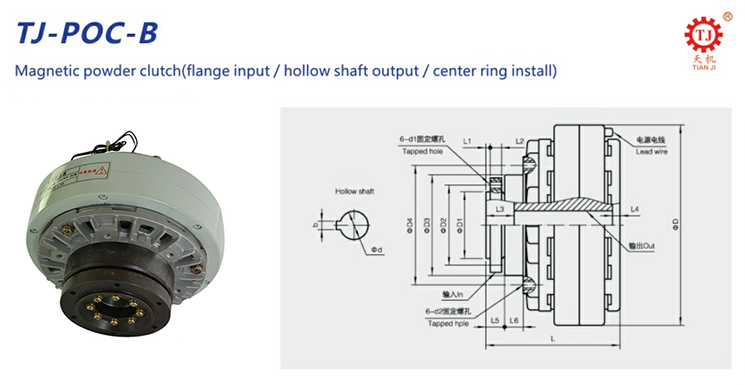

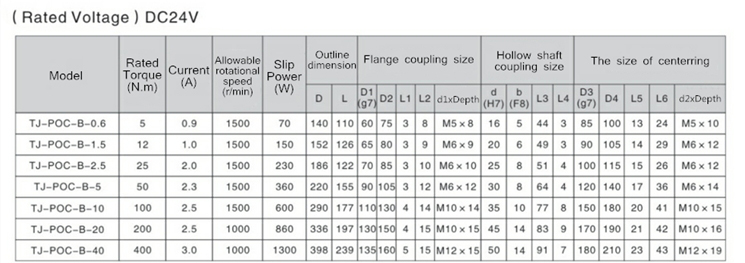

TJ-POC-B powder clutch(inner rotation)

TJ-POC-C(Micro magnetic particle clutch)

Notes:

1.Don’t overload, meanwhile cool to appropriate temperature

The value of the torque/rotational speed/slip power should be less than the rated value. The cooling mode(natural cooling/forced air cooling/water cooling) should depend on the maximum slip power when it works and the cooling air should pass the water and oil filter. The temperature detector and the alarm should be installed to prevent high temperature which can affect the service life of the magnetic powder.(the highest temperature is 80 degree)

2.Concerning the service life

The life of the magnetic powder clutch and brake rely on the life of the magnetic powder. Generally speaking, its service life is 4500-7500hours in the state of non overloaded; but its service life can extend several times in some cases, such as: the working torque of the magnetic powder clutch/brake,relative slip rotational speed and slip power can be reduced to 50%-70% of the rated value. This is to say, the margin can be enlarged as soon as possible when designing.

3.Concerning the torque

After the magnetic powder clutch and brake working, the magnetic powder will be in grinding at the beginning which leads to the torque decreasing slightly, but the gap can be compensated through adjustment the current..

Order details:

Related Products

Advantages

Why do you choose us?

Your choice,We promise!

Eight reasons to choose us:

1. Perfect service system and after-sale protection.

2. Quality problems will be solved within 24hours.

3. One-to-one customer service tracking processing.

4. Companies carry out the ERP management, improve enterprise fast response.

5. Quality assurance, one year warranty.

6. Supporting professional matched other equipments.

7. The company has more than one product testing units, the implementation of ISO9001: 2015.

8. Unique development and design capabilities to meet the needs of special-purpose equipment manufacturing.

Five Core strengths:

1. The first domestic independent R & D manufacturer and 13 years of professional manufacturing.

2. Casting exquisite, beautiful, practical and durable.

3. Complete specifications, cost-effective and spot supply.

4. Independent research and development, special specifications can be customized.

5. Selected materials, high-tech treatment, up to the international standard test.

More concerned for our products , please do not hesitate to inquiry now!

See larger image

See larger image Leave Messages

Leave Messages